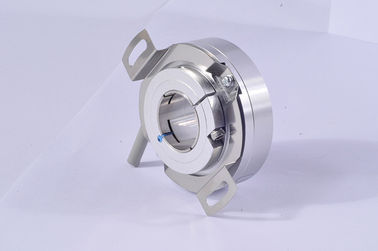

K58 servo motor rotary encoder thickness 24mm hole diameter 20mm customizable encoder

Production Catalogue

If you have already selected the encoder model you are going to order, please email us directly or contact online service right now to get the latest catalogue.

But if you are still have any doubts on choosing a right encoder model number, you are also free to contact us to get the related catalogue.

K58 Encoder Detail Specifications

| Items | Basic parameters |

| Brand | HENGXIANG |

| Encoder type | Incremental encoder |

| Output mode | NPN/PNP(Open Collector Output) |

| Voltage output | |

| Push-pull output | |

| line drive (26LS31) TTL | |

| line drive(DC8-30V) HTL | |

| TTL(DC5V) phase ABZ are back of phase UVW | |

| Consumption current | 100mA MAX |

| Top response frequency | 300KHZ |

| Allowable ripple | ≤3%rms |

| Load Voltage | ≤DC30V |

| GND | not connect to encoder |

| Mark to Space ratio | 45% to 55% |

| starting torque | less than 9.8 x 10-3 N.m |

| Intertia moment | less than 6.5x 10-6kg.m2 |

| Shaft load | Radial 50N; Axial 30N |

| Top REV | 3000RPM |

| Bearing life | 1.5x109 revs at rated load(100000hrs at 2500RPM) |

| Environmental temperature | Operating:-20 ~+85°;storage:-25 ~+90° |

| Environmental humidity | Operating and storage: 35-85%RH(noncondensing) |

| Vibration(endure) | Amplitude 1.52mm,5-55Hz,2 hours for three axis individually |

| Sock(endure) | 980m/s2 ,11 ms three times for X,Y,Z direction individually |

| Shaft Material | Stainless steel |

| Shell Material | die cast aluminum |

| Cable length | 1000mm(cable with shielding) |

| Protection grade | IP50 |

| Cable length | 1M (cable length could be added appropriately by |

| require, but it need payment individually) | |

| Certification | CE |

| package | Carton box |

| Net weight | About 150g (with package) |

ENCODER TECHNOLOGY THEORY

An incremental rotary encoder outputs a certain amount of Pulses per Revolution. The higher this PPR number, the smaller the angle between each pulse. This PPR number is fixed for ordinary incremental encoders. Programmable incremental encoders can adjust this value to a desired number by a software change.

Today most incremental encoders have a Push-Pull (HTL) or RS422 (TTL) output driver, these have replaced most of the older output circuits like Open Collector NPN, Open Collector PNP, Voltage Output.

Push-Pull (HTL) circuits, also known as Totem Pole, provide a signal level which corresponds to the applied supply voltage. The supply voltage typically ranges from 8 to 30 VDC.

With proper connections you can use the Push Pull interface to replace true open collector circuits by using an external diode connected in a way to limit the direction of the current for RS422 (TTL) circuits provide a constant 5 V signal level that is not dependent on the supply voltage. Two supply voltage ranges can be selected: From 4.75 to 5.5 VDC (can be used to replace open collector output drivers) or from 8 to 30 VDC. Using differential signals the output fully complies to the RS422 standard.

![]()

About Encoder Vibration

Vibration acting on an encoder always cause wrong pulse easily.

So we have to pay more attention to encoder working place.

The more pulse per round, the narrower groovy spacing of grating, ore effect to encoder by vibration, when motor speed is low or even stopped, vibration acting on encoder shaft or encoder shell would cause grating vibration, in this way, encoder might show wrong pulse signal.

Our Service