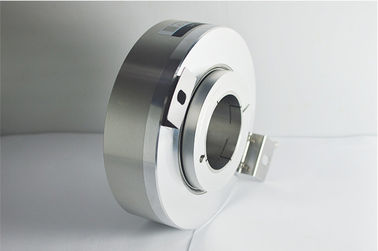

Totem pole output elevator encoder K130 hollow shaft 48mm 8192 P/R concentricity 0.05 max

Lead time

1. for 1-10 samples: 3-5 working days

2. for 20-50 mass production: 7-10 working days

3. for over 100pcs, production will be discussed with customers and ship on time

![]()

Factory Encoder Production Capability

5000 pieces per month

-------- Production Line Capacity

50000 pieces per year

--------Actual Units Produced (Previous Year)

About Our Factory

Characteristics of K130 Series rotary encoder

| Items | Basic parameters |

| Brand | HENGXIANG |

| Encoder type | Incremental encoder |

| External diameter | 158mm |

| Thickness | 43mm |

| Installation dimension | R85mm(spring plate 158T170) |

| Hollow shaft type | through hole (clamping ring at prior) |

| Hollow shaft diameter | 70mm,75mm,78mm;80mm;82mm |

| Resolution | 1024;2048;20000;40000;80000 |

| Consumption current | 100mA MAX |

| Top response frequency | 300KHZ |

| Insulation resistance | 10MΩ |

| GND | not connect to encoder |

| starting torque | less than 400 x 10-3 N.m |

| Intertia moment | less than 350x 10-6kg.m2 |

| Shaft load | Radial 90N; Axial 60N |

| Top REV | 3000RPM |

| Environmental temperature | Operating:-20 ~+80°;storage:-25 ~+85° |

| Environmental humidity | Operating and storage: 35-85%RH(noncondensing) |

| Vibration(endure) | Amplitude 1.52mm,5-55Hz,2 hours for three axis individually |

| Sock(endure) | 1960m/s2 (200g),11 ms three times for X,Y,Z direction individually |

| Shaft Material | Stainless steel |

| Shell Material | aluminum alloy |

| Cable length | 1000mm(cable with shielding) |

| Protection grade | IP50 |

| Cable length | 1M (cable length could be added appropriately by |

| require, but it need payment individually) | |

| Certification | CE |

| package | Carton box |

| Net weight | About 1800g (with package) |

Notice for encoder installation

1. Please read the encoder specification carefully before installation

2. Encoder is belong to precision instrument, so we should avoid shock or vibration to protect interior parts.

3. The power supply voltage must be holded within specified range, or encoder could be destroyed.

4. Notice coaxially requirements when you install the power shaft, please use flexible coupling and do not press encoder forcibly.

5. Shielding cable of encoder must be connected to avoid electromagnetism interference of alternating current, cables of encoder should be layout individually.

6. Wiring diagram connection should be strictly follow the specified color in catalogue, or encoder interior circuit may be destroyed

7. Encoder should be apart from powerful magnetic field, dust, oil, water, higher (lower) temperature and caustic or flammable material during working.

8. The encoder cable signal can’t be drew or bent forcibly.