-

High Light

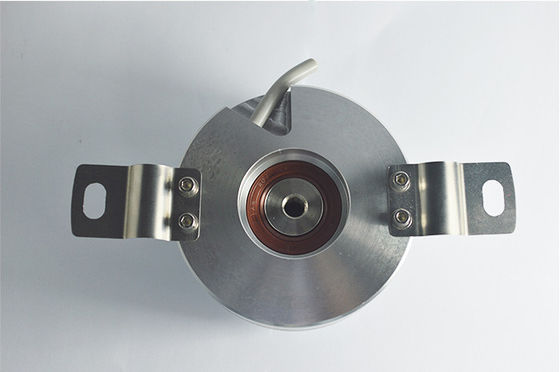

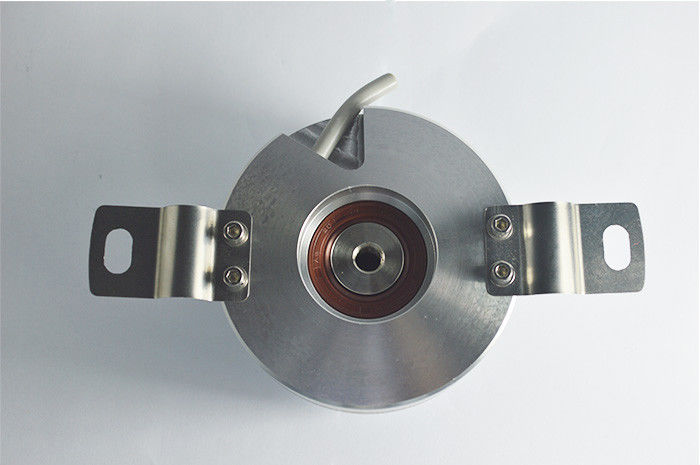

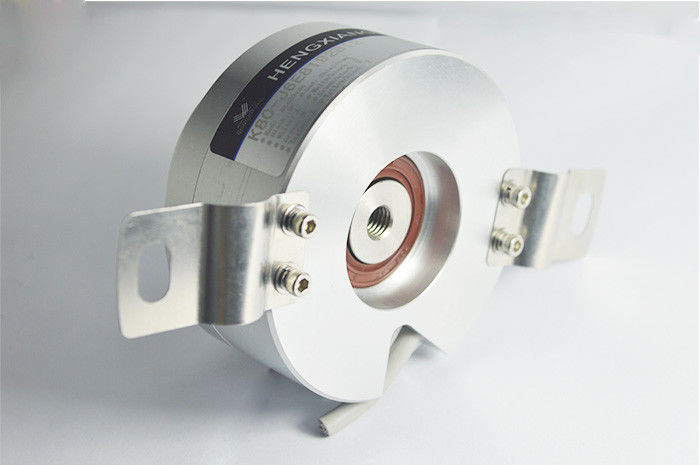

Shaft 10mm Conventional Encoder

,Totem Pole Output Conventional Encoder

,Hollow Shaft Incremental Encoders K80

-

Cable length500mm

-

External diameter80mm

-

Thickness50mm

-

Installation DimensionR60.5mm(spring Plate 76T69)

-

Hollow Shaft TypeThrough Hole

-

Hollow Shaft Diameter105mm; 12mm, Shaft Diameter Can Be Customized.

-

Output phasePhase A+,B+,Z+,A-,B-,Z-

-

Mark To Space Ratio45% To 55%

-

Place of OriginShanghai,China

-

Brand NameHENGXIANG

-

CertificationCE,ISO9001

-

Model NumberConventional encoder K80

-

Minimum Order Quantity1pcs encoder to start order

-

Pricenegotiable

-

Packaging Detailseach 1 piece was packed into single carton box

-

Delivery Time3-5 working days for sample order, 7-15 working days for mass order

-

Payment TermsD/A, D/P, T/T, Western Union, Credit Card, Master Card,Paypal, etc

-

Supply Ability100K pieces per year

Totem Pole Output Shaft 10mm Conventional Encoder K80

Conventional encoder K80 totem pole output shaft 10mm blind hole encoder cable with socket

Key Features of K80 Hollow shaft encoder

Protection grade: IP50;IP65

External diameter: 80mm

Installation dimension: R60.5mm(spring plate 76T69)

Hollow shaft diameter: 105mm; 12mm, shaft diameter can be customized.

Vibration(endure): Amplitude 1.52mm,5-55Hz,2 hours for three axis individually

Sock(endure): 1000m/s2 ,11 ms three times for X,Y,Z direction individually

Mark to Space ratio: 45% to 55%

starting torque: less than 20m N.m

Top response frequency: 300KHZ

Our advantage

· Over 18 years encoder production experience

· More than 20 years experienced engineers

· Professional working team

· High quality standard

· Quick Response time

· Utility Model Patent Certificate

· Own brand and unique brand

· CE certification for all models

· Prompt delivery date

· 100% full inspection before shipment

K80 series encoder Detail Specifications

| Items | Basic parameters |

| Encoder type | Incremental encoder |

| Brand | HENGXIANG |

| External diameter | 80mm |

| Thickness | 50mm |

| Installation dimension | R60.5mm(spring plate 76T69) |

| Hollow shaft type | through hole |

| Hollow shaft diameter | 105mm; 12mm, shaft diameter can be customized. |

| Resolution | 1000;1024;1200;1800;2000;2048;2500;3000;3600;4096;5000; |

| 7200;8192;10000;14400;16384;28800;32768 | |

| Output phase | Phase A+,B+,Z+,A-,B-,Z- |

| Supply voltage | DC5V ; DC8-30V |

| Mark to Space ratio | 45% to 55% |

| starting torque | less than 20m N.m |

| Intertia moment | less than 25x 10-6kg.m2 |

| Shaft load | Radial 50N; Axial 30N |

| Top REV | 2000RPM ;IP65≤1500 RPM |

| Bearing life | 1.5x109 revs at rated load(100000hrs at 2500RPM) |

| Environmental temperature | Operating:-20 ~+85°;storage:-25 ~+90° |

| Environmental humidity | Operating and storage: 35-85%RH(noncondensing) |

| Vibration(endure) | Amplitude 1.52mm,5-55Hz,2 hours for three axis individually |

| Sock(endure) | 1000m/s2 ,11 ms three times for X,Y,Z direction individually |

| Shaft Material | Stainless steel |

| Shell Material | die cast aluminum |

| Cable length | 1000mm(cable with shielding) |

| Protection grade | IP50;IP65 |

![]()

Encoder Operation method

A logic gate interprets certain input voltages as high (logic 1) or low (logic 0).

TTL (transistor-transistor-logic): A signal above 2 V is interpreted as logic 1 and a signal less than 0.8 V is interpreted as logic 0. The output voltage ranges between 0-5 V.

HTL (high-threshold-logic): A signal above 3 V is a logic 1 and a signal less than 1 V is a logic 0. The high output signal level is dependent from the supply voltage. Because of the higher voltage difference between logic 0 and 1, the HTL logic is more immune to interference and more resistant against electrical noise.

Mechanical degree is the actual rotation of the shaft in degrees. Electrical degree is used for electrical signals. The required time for completing one alternating voltage/current cycle is defined as 360 electrical degrees (el°). For incremental encoders, one cycle is equal to one complete pulse. With a given PPR the electrical degree can be converted to mechanical degree for any incremental encoder.

Every 90 el° the incremental encoder outputs a rising or falling edge on the “A” or “B” output that can be interpreted as a count. If an encoder outputs 1000 PPR, a counter can interpret 4000 counts (4 counts each pulse).

Factory Encoder Production Capability

5000 pieces per month

-------- Production Line Capacity

50000 pieces per year

--------Actual Units Produced (Previous Year)