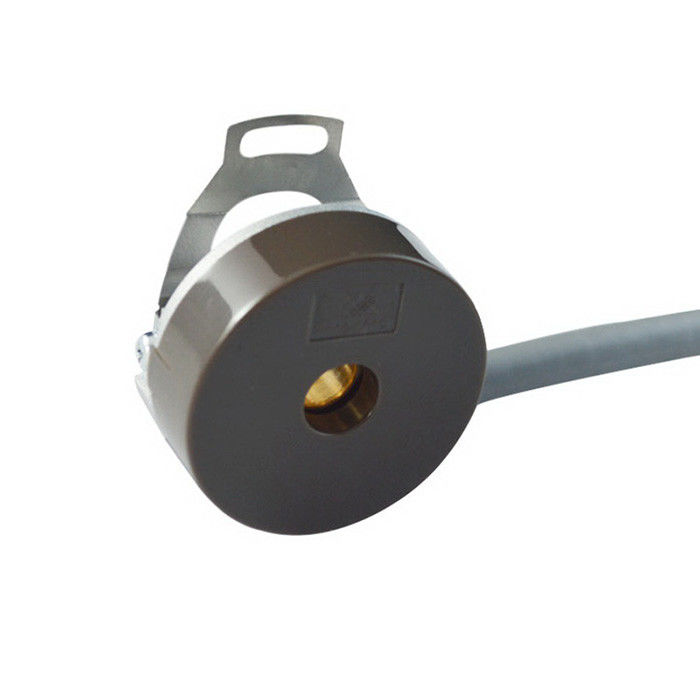

Robotic Part Optical Rotary Encoders Cnc Automation UVW Signal Servo Motor

-

High Light

Robotic Part Optical Rotary Encoders

,Cnc Automation Incremental Rotary Encoder

,UVW Signal Servo Motor Optical Encoder

-

Encoder TypeOptical Rotary Encoders

-

Shaft Type6mm/7mm/8mm (Blind Hole/Taper Hole)

-

ResolutionUp To 14400ppr

-

ApplicationServo Motor, Robotic Part Cnc Automation

-

Protection GradeIP40

-

External Diameter35mm

-

Supply VoltageDC5V; DC8-30V

-

Output PhaseAB/ABZ/±AB/±ABZ/±ABZUVW

-

Output TypeOC/Voltage/Push-pull/TTL/HTL

-

Outlet TypeRadial Cable

-

Place of OriginShanghai, China

-

Brand NameHENGXIANG

-

CertificationCE,ISO9001

-

Model NumberKN35

-

Minimum Order Quantity1pcs encoder to start order

-

Pricenegotiable

-

Packaging Detailseach 1 piece was packed into single carton box

-

Delivery Time3-5 working days for sample order, 7-15 working days for mass order

-

Payment TermsD/A, D/P, T/T, Western Union, Credit Card, Master Card,Paypal, etc

-

Supply Ability100K pieces per year

Robotic Part Optical Rotary Encoders Cnc Automation UVW Signal Servo Motor

1. Feature: Through/Blind/Taper shaft incremental encoder.

2. Application: Servo motor, CNC and other industrial automations.

3. Important parameters: UVW signal encoder, Ultra-thin, pole encoder.

| Items | Basic parameters | |

| Encoder type | Incremental encoder | |

| Brand | HENGXIANG | |

| External diameter | 35mm | |

| Thickness | 18mm | |

| Installation dimension | R13.5mm, R14.5mm, R20mm | |

| Hollow shaft type | blind hole; through hole, taper hole | |

| Hollow shaft diameter | 6mm,7mm;8mm;10mm | |

| Resolution | 1024;2048;2500;3600;5000;7200;10000;14400 | |

| 1000/4;1000/6;1000/8;1024/4;1024/6;1024/8;2000/4;2000/6;2000/8;2048/4;2048/6;2048/8;2500/4;2500/6; 2500/8;4096/4;4096/6;4096/8;5000/4;5000/6;5000/8 |

||

| Output phase | Phase A+,B+,Z+,A-,B-,Z-,U+,V+,W+,U-,V-,W- | |

| Supply voltage | DC5V ; DC8--30V | |

| Outlettype | Cable out from side | |

| Output mode | NPN/PNP(Open Collector Output) | |

| Voltage output | ||

| Push-pull output | ||

| line drive (26LS31) TTL | ||

| line drive(DC8-30V) HTL | ||

| TTL(DC5V) phase ABZ are back of phase UVW | ||

| Protection grade | IP40 | |

| Cable length | 500mm | |

| Consumption current | 100mA MAX | |

| Top response frenquency | 300KHZ | |

| Allowable ripple | ≤3%rms | |

| Load Voltage | ≤DC30V | |

| Insulation strength | AC500V 60s | |

| Insulation resistance | 10MΩ | |

| GND | not connect to encoder | |

| Mark to Space ratio | 45% to 55% | |

| starting torque | less than 5.9x 10-3 N.m | |

| Intertia moment | less than 1.5x 10-6kg.m2 | |

| Shaft load | Radial 30N; Axial 20N | |

| Slew speed | 5000RPM | |

| Bearing life | 1.5x109 revs at rated load(100000hrs at 2500RPM) | |

| Environmental temperature | Operating:-20 ~+100°C;storage:-25 ~+100°C | |

| Enviromental humidity | Operating and storage: 35-85%RH(noncondensing) | |

| Vibration(endure) | Amplitude 0.75mm,5-55Hz,2 hours for three axis individually | |

| Sock(endure) | 490m/s2 ,11 ms three times for X,Y,Z direction individually | |

| Shell Material | Dia cast aluminium | |

| Certification | CE | |

| package | Carton box | |

| Net weight | About 80g (with package) | |

FAQ:

Q: Are you a factory or a trading company?

A: we are 100% factory with our brand.

Q: What’s your brand?

A: HENGXIANG

Q: How to select a right encoder model?

A: A right encoder model is based on different applications and parameters, you could contact us for technical support if you have any query.

Q: Do you offer technical support?

A: Yes, we have professional technician who can solve all your doubts.

Q: What’s your encoder product guarantee policy?

A: 1 year quality warranty and life-long technical support.

Q: Where can I download the encoder catalogue or datasheet?

A: You could visit our official website or email us directly to the latest files.

Q: Where is your factory?

A: Our factory is located on Shanghai City.

Q: Do you test your encoder product before shipment?

A: Yes, we 100% test and examine every piece before shipping to make sure it work well on your device.

Matters needing attention:

1. Please read the encoder specification carefully before installation

2. Encoder is belong to precision instrument, so we should avoid shock or vibration to protect interior parts.

3. The power supply voltage must be holded within specified range, or encoder could be destroyed.

4. Notice coaxially requirements when you install the power shaft, please use flexible coupling and do not press encoder forcibly.

5. Shielding cable of encoder must be connected to avoid electromagnetism interference of alternating current, cables of encoder should be layout individually.

6. Wiring diagram connection should be strictly follow the specified color in catalogue, or encoder interior circuit may be destroyed

7. Encoder should be apart from powerful magnetic field, dust, oil, water, higher (lower) temperature and caustic or flammable material during working.

8. The encoder cable signal can’t be drew or bent forcibly.