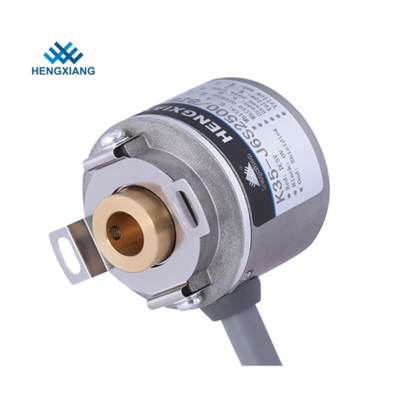

Blind hole 8mm external diameter 35mm K35 miniature rotary encoder 40mm leaf spring

Key Features of K35 servo motor encoder

Bearing life: 1.5x109 revs at rated load(100000hrs at 2500RPM)

Environmental temperature: Operating:-20 ~+80°;storage:-25 ~+90°

Vibration(endure): Amplitude 0.75mm,5-55Hz,2 hours for three axis individually

Sock(endure): 490m/s2 ,11 ms three times for X,Y,Z direction individually

Certification: CE

Top REV: 5000RPM

Mark to Space ratio: 45% to 55%

Shaft load: Radial 30N; Axial 20N

Some Related K35 encoder model number

K35-J12C2500/8B6 DC5V spring plate 35T40

K35-J12L2000/4B8 DC5V spring plate 35T29

K35-J3N2500/16B10 DC5-12V spring plate 35T29

K35-J3F1200B6 DC12-24V spring plate 35T29

K35-J6S2500/8B8 DC5V spring plate 35T29

K35-J6C2000B10 DC5V spring plate 35T40

K35-J6E720B6 DC8-30V spring plate 35T29

K35-J12C1000/4B8 DC5V spring plate 35T40

K35-J12L2048/6B10 DC5V spring plate 35T40

Specification

| Items | Basic parameters |

| Brand | HENGXIANG |

| Encoder type | Incremental encoder |

| External diameter | 35mm |

| Thickness | 35mm |

| Installation dimension | 40mm(spring plate 35T40); 29mm(35T29) |

| Hollow shaft type | blind hole |

| Hollow shaft diameter | 6mm,8mm;10mm |

| Resolution | 30;36;50;60;100;200;250;256;300;360;400;450;500;512;600; 1000;1024;1200;2000;2048;2500; 4096;5000 |

| 1000/4;1000/6;1000/8;1024/4;1024/6;1024/8;2000/4;2000/6;2000/8;2048/4;2048/6;2048/8;2500/4;2500/6;2500/8;4096/4;4096/6;4096/8;5000/4;5000/6;5000/8 | |

| Output phase | Phase A+,B+,Z+,A-,B-,Z-,U+,V+,W+,U-,V-,W- |

| Supply voltage | DC5V & DC8--30V |

| Outlet type | Cable out from side |

| Output mode | NPN/PNP(Open Collector Output) |

| Voltage output | |

| Push-pull output | |

| line drive (26LS31) TTL | |

| line drive(DC8-30V) HTL | |

| TTL(DC5V) phase ABZ are back of phase UVW | |

| Protection grade | IP50 |

| Cable length | 500mm |

![]()

Our Selling points

About Encoder Vibration

Vibration acting on an encoder always cause wrong pulse easily.

So we have to pay more attention to encoder working place.

The more pulse per round, the narrower groovy spacing of grating, ore effect to encoder by vibration, when motor speed is low or even stopped, vibration acting on encoder shaft or encoder shell would cause grating vibration, in this way, encoder might show wrong pulse signal.

About Our Factory

More information

If you are looking for more information about our factory or about our products, please contact us or email us right now, we will reply you as soon as possible.