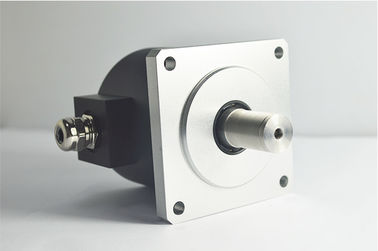

Keyway heavy duty encoder solid shaft 15mm SC65F 6 phase line driver output dc8-30v

Advantage of “HENGXIANG” encoder factory

![]()

Applications

Product Information for SC65F incremental encoder

| Items | Basic parameters |

| Brand | HENGXIANG |

| Encoder type | Incremental encoder |

| External diameter | 65mm |

| Thickness | 58mm |

| Flange dimension | 68mm x 68mm |

| Installation dimension | 56mm x 56mm |

| Shaft length | 26mm |

| Solid Shaft diameter | 15mm( KEYWAY 5mm) |

| Resolution | 50;60;100;200;250;256;300;360;400;450;500;512;600;720;1000 |

| 1000;1024;1200;1250;1440;1800;2000;2048;2500;2880;3000; | |

| 3600;4000;4096;5000;5760;8192;10000;11520;16384;20000; 23040 | |

| Output phase | Phase A+,B+,Z+,A- B- Z- |

| Supply voltage | DC5V ; DC8-30V |

| Outlet type | Radial cable |

| Radial socket | |

| NPN/PNP(Open Collector Output) | |

| Voltage output | |

| Output mode | Push-pull output |

| line drive (26LS31) TTL | |

| line drive(DC8-30V) HTL | |

| Protection grade | IP50 ; IP65 |

| Top REV | 5000RPM ;IP65≤3000 RPM |

| Bearing life | 1.5x109 revs at rated load(100000hrs at 2500RPM) |

| Environmental temperature | Operating:-20 ~+80°;storage:-25 ~+85° |

| Environmental humidity | Operating and storage: 35-85%RH(noncondensing) |

| Vibration(endure) | Amplitude 0.75mm,5-55Hz,2 hours for three axis individually |

| Sock(endure) | 490m/s2 ,11 ms three times for X,Y,Z direction individually |

| Shaft Material | Stainless steel |

| Shell Material | die cast aluminum |

Factory Encoder Production Capability

5000 pieces per month

-------- Production Line Capacity

50000 pieces per year

--------Actual Units Produced (Previous Year)

Notice for encoder installation

1. Please read the encoder specification carefully before installation

2. Encoder is belong to precision instrument, so we should avoid shock or vibration to protect interior parts.

3. The power supply voltage must be holded within specified range, or encoder could be destroyed.

4. Notice coaxially requirements when you install the power shaft, please use flexible coupling and do not press encoder forcibly.

5. Shielding cable of encoder must be connected to avoid electromagnetism interference of alternating current, cables of encoder should be layout individually.

6. Wiring diagram connection should be strictly follow the specified color in catalogue, or encoder interior circuit may be destroyed

7. Encoder should be apart from powerful magnetic field, dust, oil, water, higher (lower) temperature and caustic or flammable material during working.

8. The encoder cable signal can’t be drew or bent forcibly.